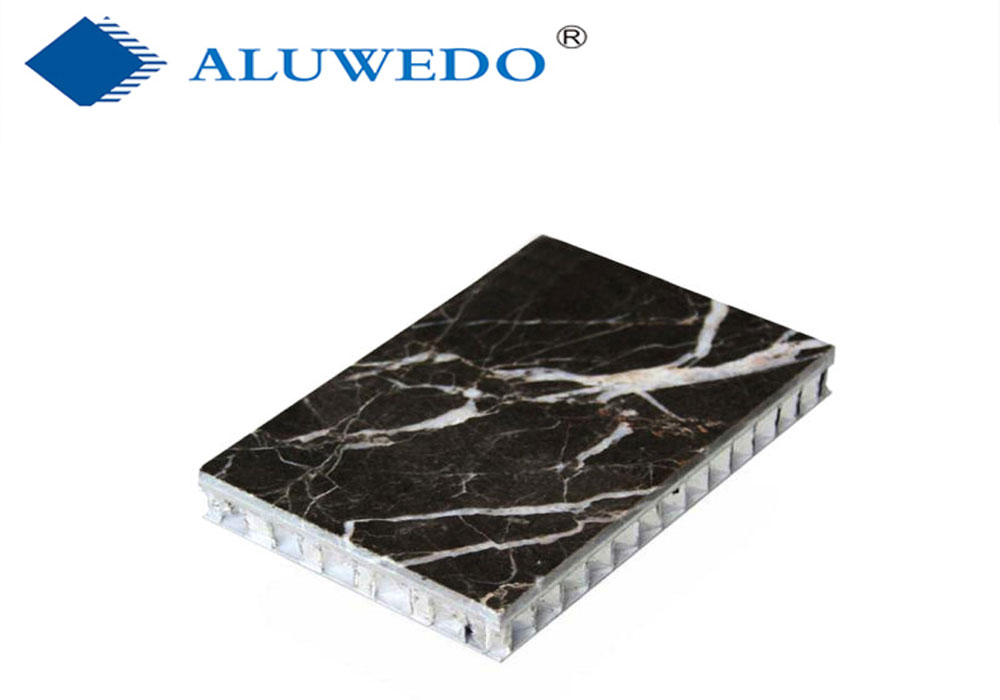

Stone Honeycomb Panel

- Mobile: +86-13962238789

- whatsapp: 008613962238789

- wechat: 008613962238789

- E-mail: [email protected]

Introduction

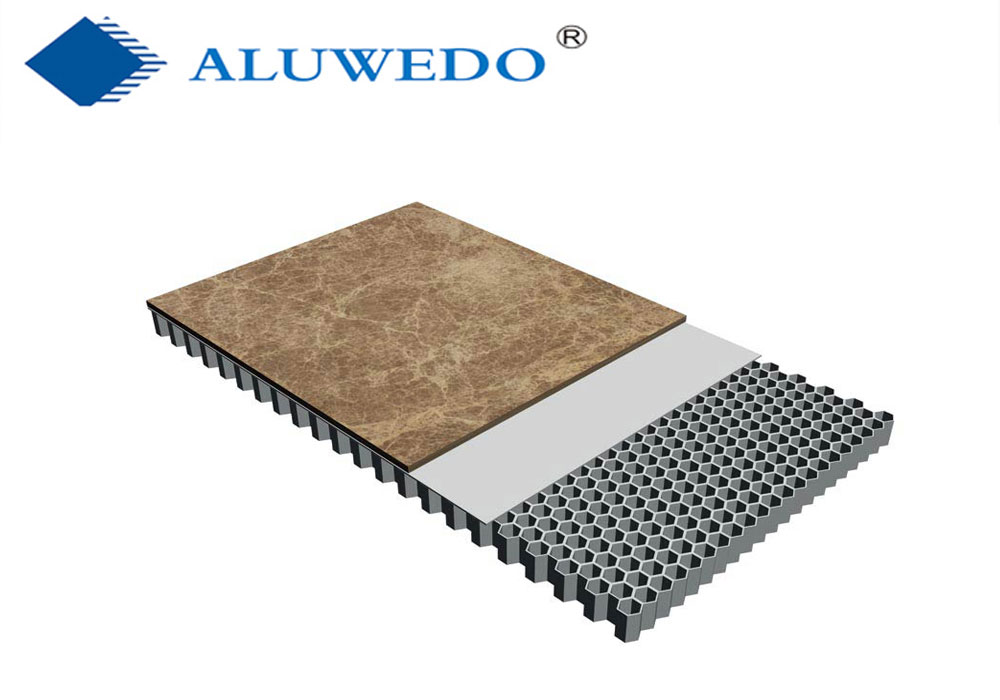

SYSTEM COMPOSITION

ADVANTAGES

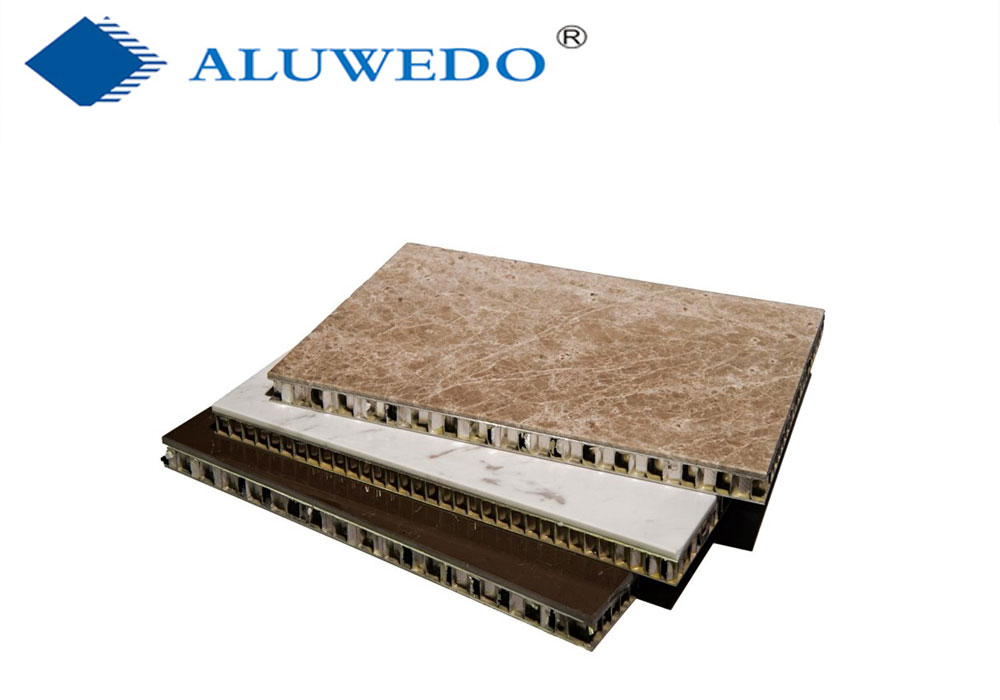

As a decorative material, natural stone is generally expensive, and has natural defects such as a heavy weight, unstable physical structure and color difference. However, Aluwedo’s natural stone honeycomb panel has some special advantages compared to traditional stone. Natural stone veneer on aluminum honeycomb panels increases the raw material usage area in practical applications, thus greatly cutting down the weight, reducing the color difference in the stone, improving the physical structure of the stone, and significantly increasing installation convenience through interlocking clips, which also widens the stone application scope, such as cladding in high rise buildings.

COMPARISON OF STONE HONEYCOMB PANELS WITH TRADITIONAL STONE SLABS

| Traditional Stone Slabs | Stone Honeycomb Panels | |

| Weight Comparison | 30mm Total thickness 75kg/㎡ weight | 20mm Total thickness 15kg/㎡ weight |

| Performance Comparison | Unable to bend | Bendable (pressing 30mm bent not crack) |

| Installation | Big expenditure | Small expenditure (100yuan/㎡) |

| Safety Performance | Cracking in impact-resistant test | Only with punctate cracking |

| Material Availability | Useful material output from one cubic | 80-100㎡ |

| Maximum Size | ≦600*600 | Able to reach 1600*3200 |

BENDABLE STONE HONEYCOMB PANEL

The bendable natural stone honeycomb panel developed by Aluwedo consists of a 1-2 mm stone veneer panel and aluminum honeycomb backing. The special technology used in this panel has been awarded a national patent and continuously optimized in projects over the past few years. The current accuracy of finished bendable panels reach within millimeter tolerances.

Compared with the traditional curved stone panels processed by cutting, the bendable stone panel has a larger surface, is energy-saving, environmentally friendly, easy to install, and more economical due to the reduced stone usage.

The bendable natural stone honeycomb panels feature a wide application range. For stones with a low brittleness, the minimum bending radius is 600mm; for stones with a high brittleness, the minimum bending radius is generally 1000mm.

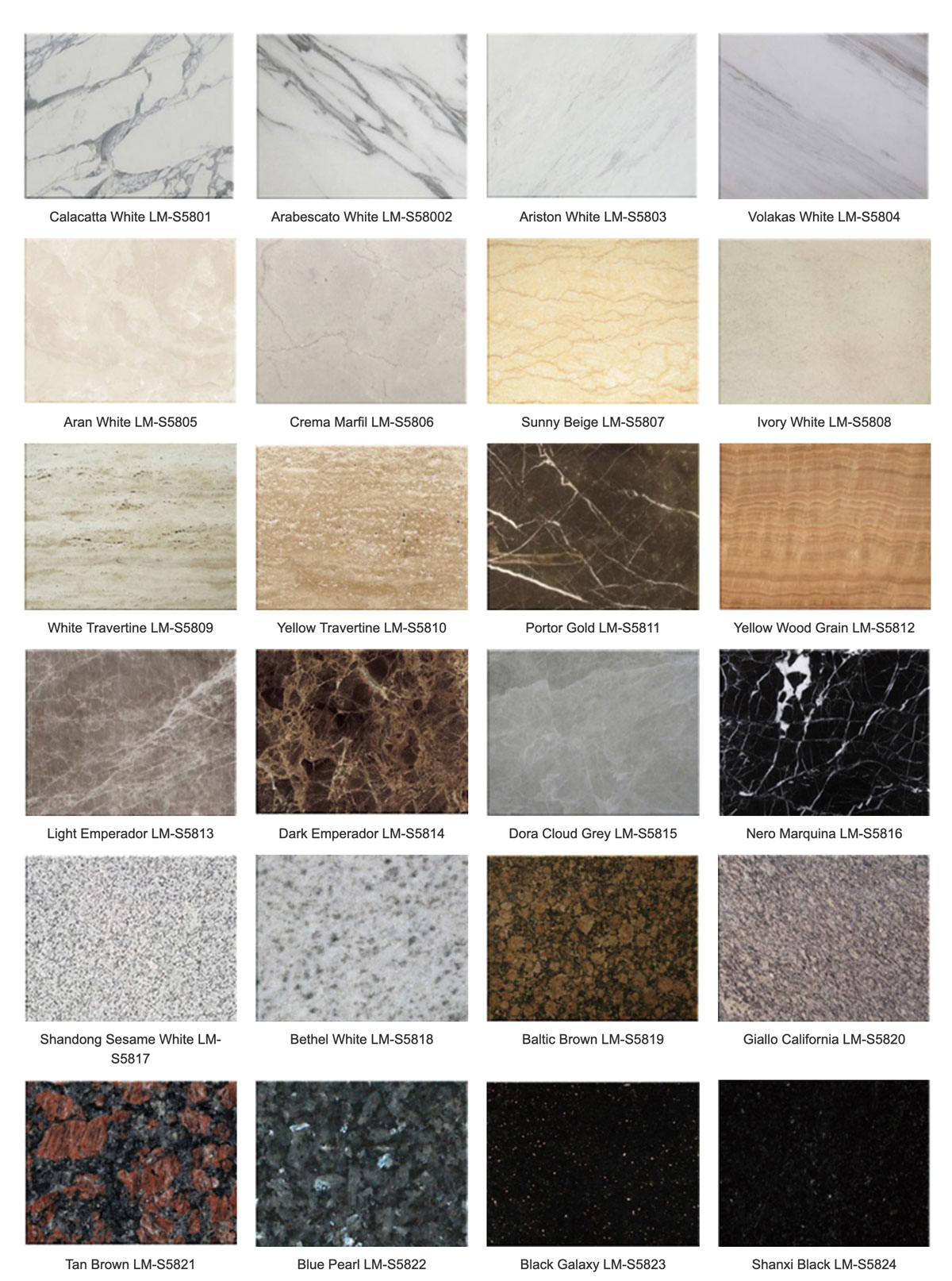

PANEL SELECTION

STONE HONEYCOMB PANEL DATA SHEET

| Items | Test Results | Tested By | Report Number |

| Flatwise tensile strength | Average value: 2.73MPa Minimum value: 2.56MPa | CTC | 2013102031 |

| Flatwise compressive | 2.44MPa | CTC | 2013102031 |

| Flatwise compressive elastic modulus | 122.4MPa | CTC | 2013102031 |

| Flatwise shear strength | 1.16MPa | CTC | 2013102031 |

| Flatwise shear compressive | 8.03MPa | CTC | 2013102031 |

| Flexural strength | 138 5MPa | CTC | 2013102031 |

| Flexural rigidity | 1.27*10^9N·mm/mm² | CTC | 2013102031 |

| Shearing rigidity | 3.08*10^5N | CTC | 2013102031 |

| Climbing drum peel strength | Average value: 106N·mm/mm Minimum value: 93N·mm/mm | CTC | 2013102031 |

| Bearing capacity of fittings | 3.6kN | CTC | 2013102031 |

| Anti-freezing | Appearance: no abnormalities average decrease percentage of flatwise adhesive strength: 12% | CTC | 2013102031 |

| Temperature difference resistance | Appearance: no abnormalities average decrease percentage of of flexural rigidity : 16% | CTC | 2013102031 |

| Hot water resistance | Appearance: no abnormalities average decrease percentage of flatwise adhesive strength: 11% | CTC | 2013102031 |