01 Products

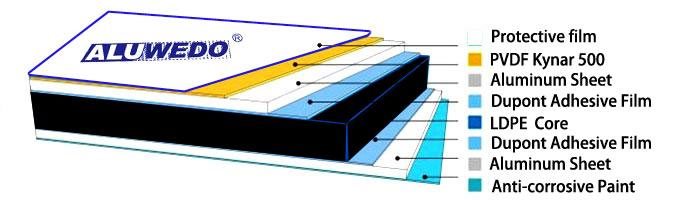

Structure

3/5 series pre-roll coated aluminum panel

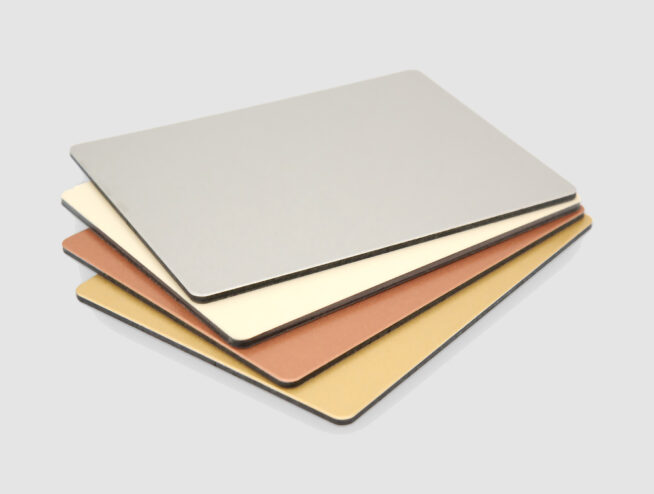

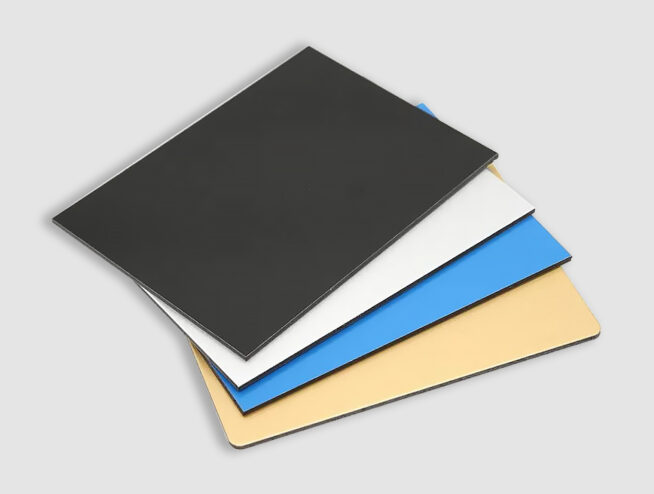

Standard series

Spectra series

Velvet series

Texture series

Diffuse series

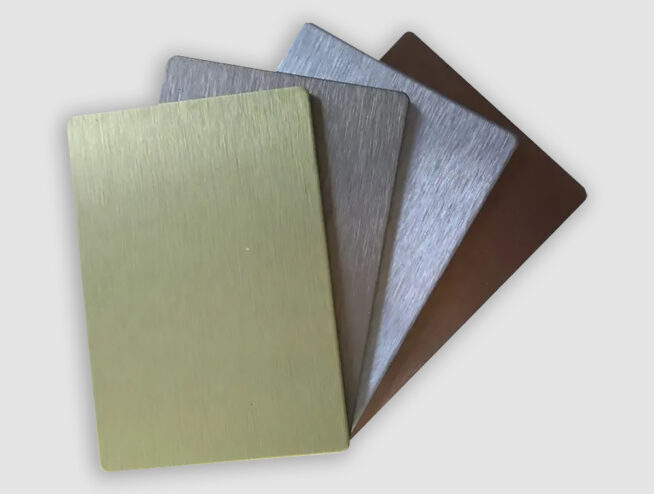

Brushed series

Mirror series

Wooden series

Stone series

Stainless steel series

Pure titanium series

Titanium zinc series

Galvanized steel series

FR flame retardant core

HFR high flame -retarded core

A2 non-combustible core

A1 non-combustible core

Back Material

3/5 series pre-roll coated aluminum panel

Copper series

Stainless steel series

Pure titanium series

Titanium zinc series

Galvanized steel series

02 Specification

Structure

| raw material | specification | parameter |

| base material:3/5-series high-strength aluminum or other metal | thickness:3-6mm | recommend:4mm |

| coating:PVDF、FEVE High weather resistant coating | width:1000-2000mm | recommend:1220mm、 1250mm、 1500mm |

| core:B1、FR、HFR、A2、A1、Alu honeycomb core/ Alu corrugated core/ Alu Sandwich core | length:customizable (<12m) | recommend:2440mm、 3050mm、 4050mm |

03 Product Details

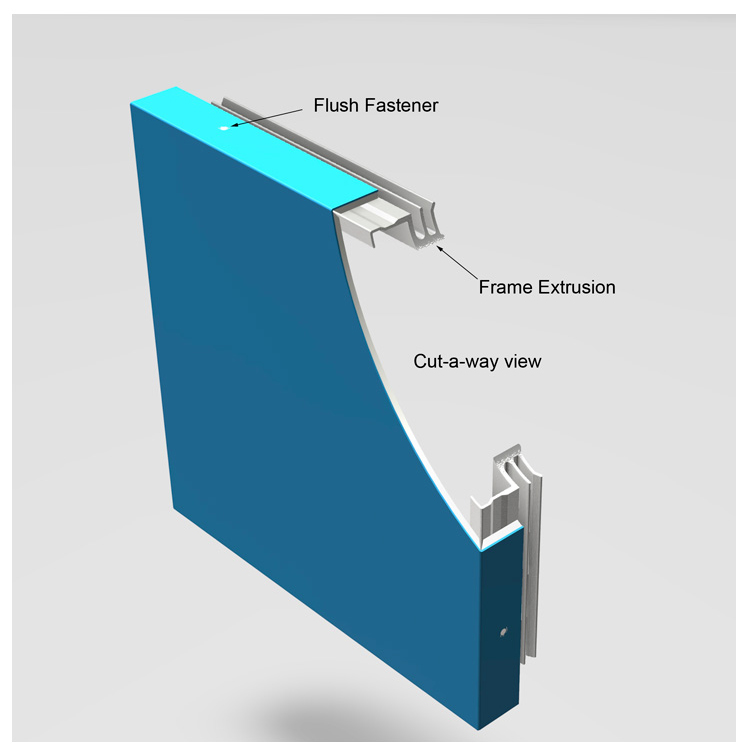

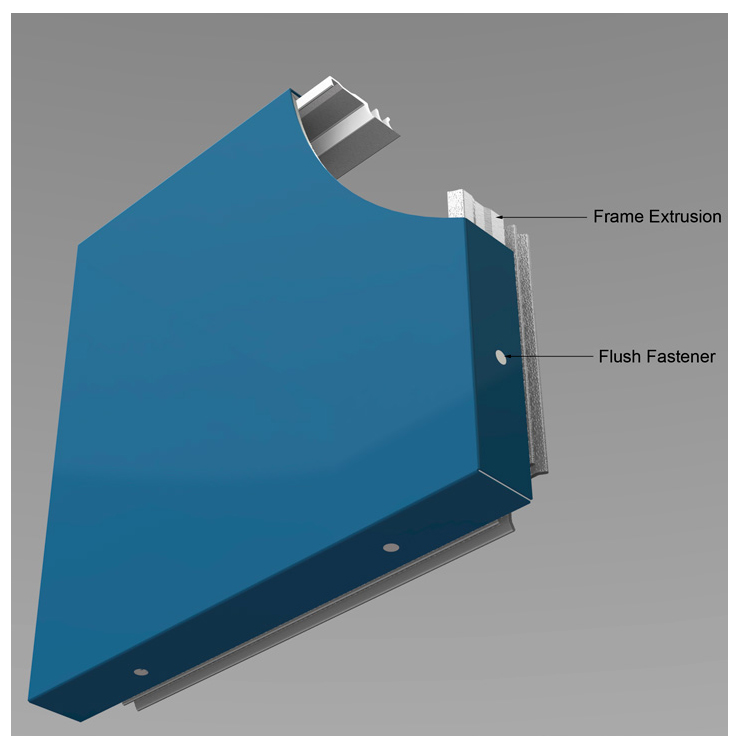

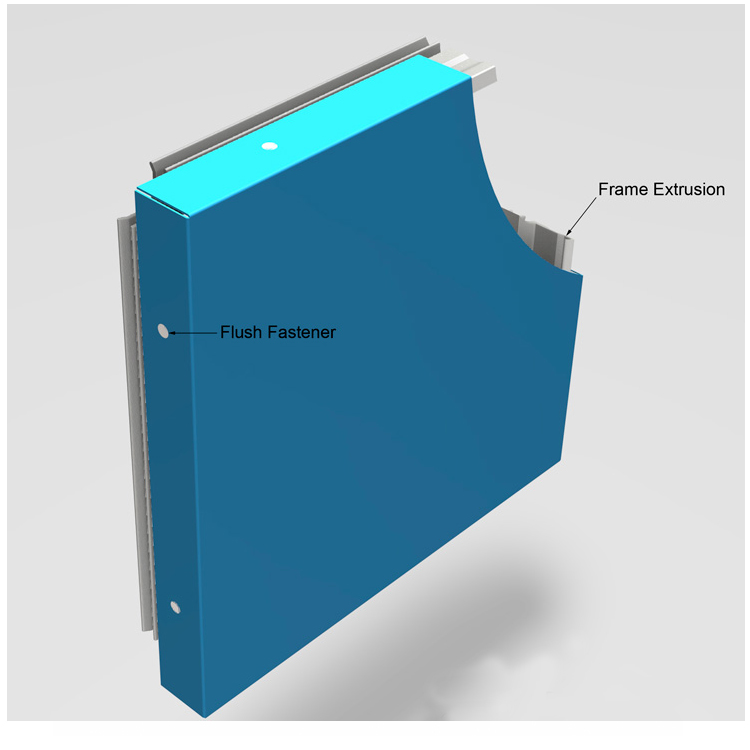

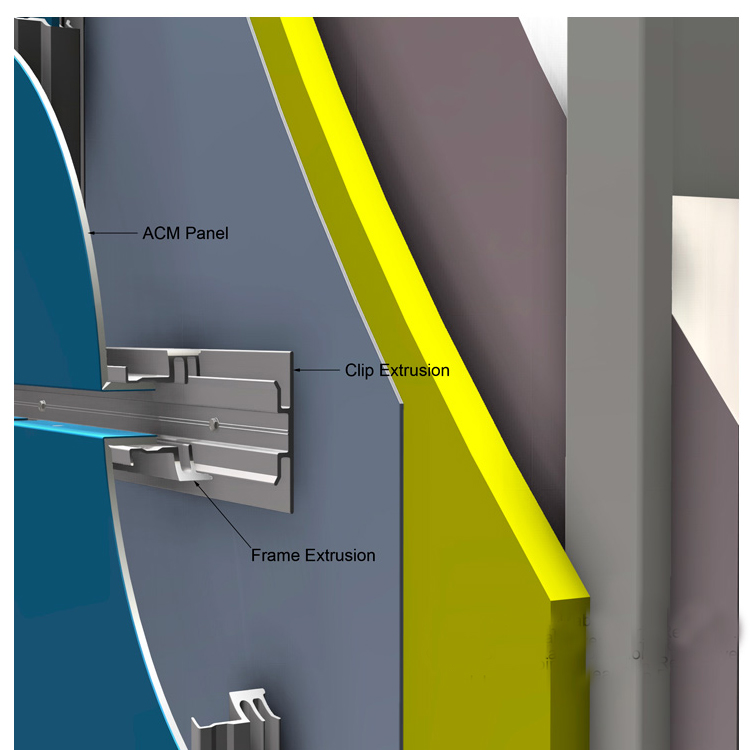

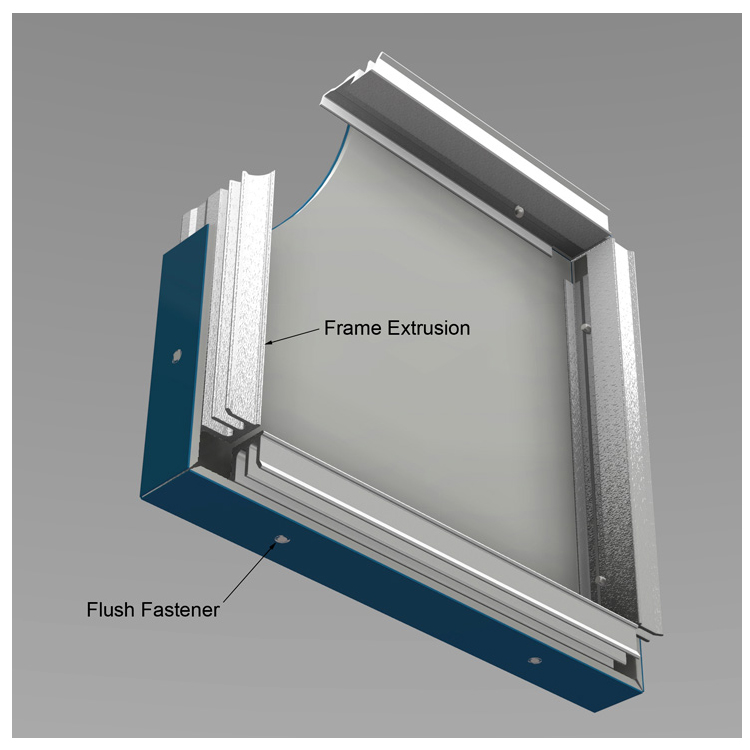

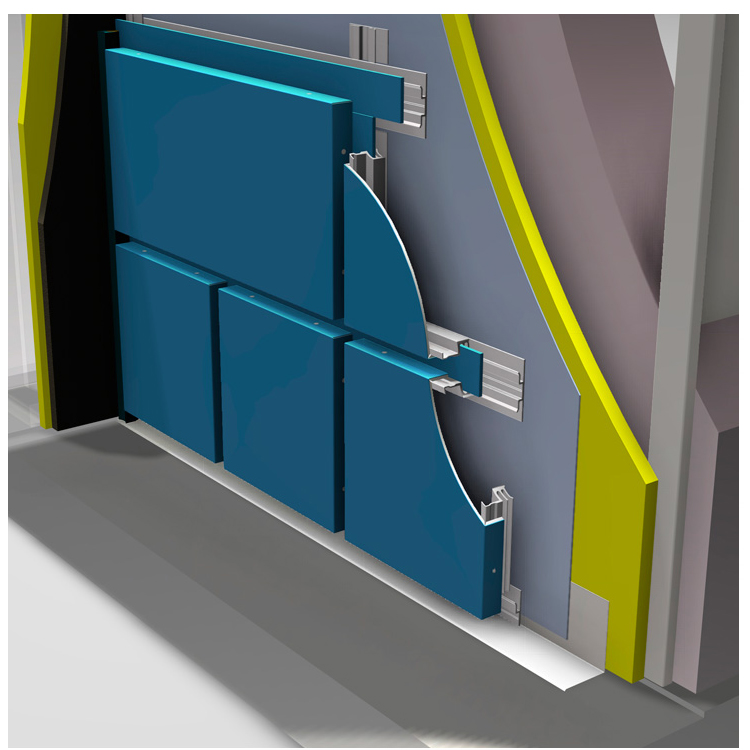

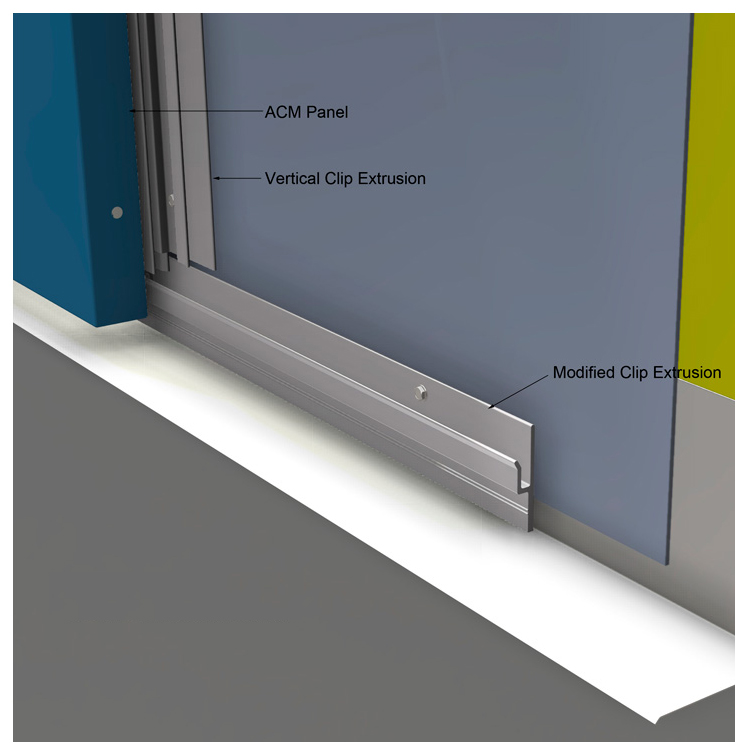

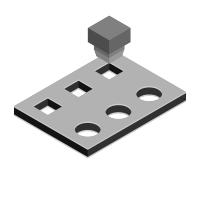

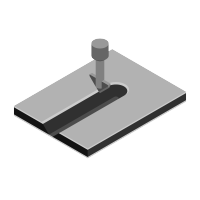

Install ways

The composite panel can be punched and die-cut with CNC. The result ranges from the creation of pointillist or artistic style patterns to complicated and detailed drawings on the facade

· Simple, which hides the edging · Double interior, hides the edge and part of the back · Double outside, hides the edge and extends a flange that hides the joints with other panel sheets.

The panel can be easily bent following the minimum necessary bending radii. To do it, it is best to use bending machines with 3/4 rolls.

By bending the product, columns can be covered, concealing the corners with a rounded appearance, etc.

With more limitations than the previous transformations, we find that in the panel, through modifications in its depth, it is possible to make engravings creating forms without having to get to cut-die the panel.

The 3D forming process, besides of being used to manufacturing aluminium composite panel for hanging systems, can also be used to create projected three-dimensional surfaces.

The milling of the panel gives results that differ from other types of processing such as punching and, of course, from the usual conception of the composite panel as a cassette-type tray. It can be made with CNC, with a wall saw or a portable one. The partial milling of the panel allows the subsequent folding of the pieces to give them creative shapes.

Easy Way on on the wall

04 Cases

Country:Israel

Products: Fireproof B1 Nano coating Aluminum Composite Panel

Quantity:8,000sqms

Country:Israel

Products: Fireproof Aluminum Composite Panel

Quantity:2,500sqms

Country:Israel

Products: Fireproof Aluminum Composite Panel

Quantity:12,000sqms

Country:Bosnia and Herzegovina

Year: 2010

Project Name:Gas stations

Products: Aluminum Composite Panel

Quantity:3,000sqms

Country:China

Year: 2021

Project Name:Hiphi

Products: Aluminum Composite Panel

Quantity:25,000sqms

Country:Cyprus

Products: Aluminum Honeycomb Panel

Quantity:3,000sqms

05 FAQ

Frequently Asked Questions about Aluminium Composite Panel for building

What are Aluminium Composite Panels?

What material is used for the core?

What’s your delivery time?

Do you sell any related products which are used for installing the aluminum composite panel?